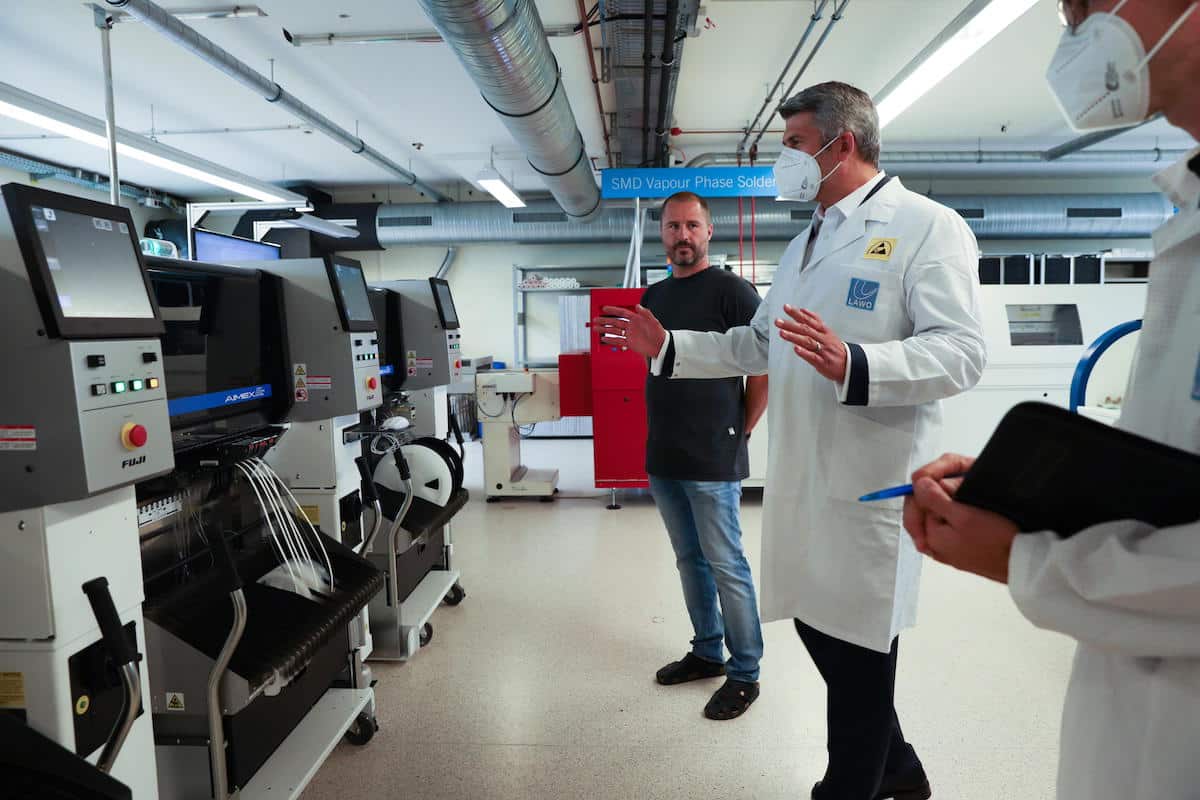

Lawo is preparing for increasing product demand with its investment in a state-of-the-art, high-precision SMD production line from Fuji Europe Corporation GmbH.

The company develops, manufactures and distributes advanced network, control, audio and video systems for TV and radio, industry, live sound and theater applications. Manufacturing is at the company’s headquarters in Rastatt, Germany, where it employs about two-thirds of its approximately 300 worldwide employees. Lawo has invested in three new Fuji AIMEX-series pick-and-place machines, which can assemble around 30,000 components per hour of even the smallest component size, EIA 01005, equivalent to twice the diameter of a human hair.

Stefan Janssen, managing director of Fuji Europe Corporation GmbH, explains, “AIMEX IIIc is a machine platform that enables any type of production and changes in the package shapes used. It supports in one machine the processing of smallest chip components up to large components. At the same time, it is possible to easily ramp up new productions or react to changes in package shapes. This creates a high degree of flexibility.”

Investing to remain independent

Christian Lukic, chief supply chain officer at Lawo, is justifiably proud. “With this significant investment of around one million euros in our Rastatt production line, we are securing Lawo’s future viability as a manufacturer of high-quality hardware products and ensuring that we can continue to map the full vertical range of manufacture within the company. This enables us to remain independent in the future and to ensure our quality standards as befits a premium broadcast and media technology manufacturer.”

The new production line also includes an integrated vapor phase soldering furnace and automated component storage cabinets, which save working time and space and extend the shelf life of parts and components.

“This sophisticated new production line works much more precisely than its predecessor,” says Lukic. “It reduces the possibility of errors nearly to zero and reduces setup times while significantly increasing placement speed — a clear step towards Lawo’s continued successful future.”

More RedTech news about Lawo

Lawo virtualization fires up Kigali’s 104.1 Power FM