Broadcast antenna and RF system manufacturer Dielectric looks to change how to validate directional pattern studies for new FM broadcast antennas. Together with consultancy Merrill Weiss Group, it has filed a Petition for Rulemaking with the United States Federal Communications Commission and expects it to be approved later this year.

The rule change passes the torch from physical to AI-driven simulated modeling. If passed, it will be the first directional FM pattern verification rule change in 58 years.

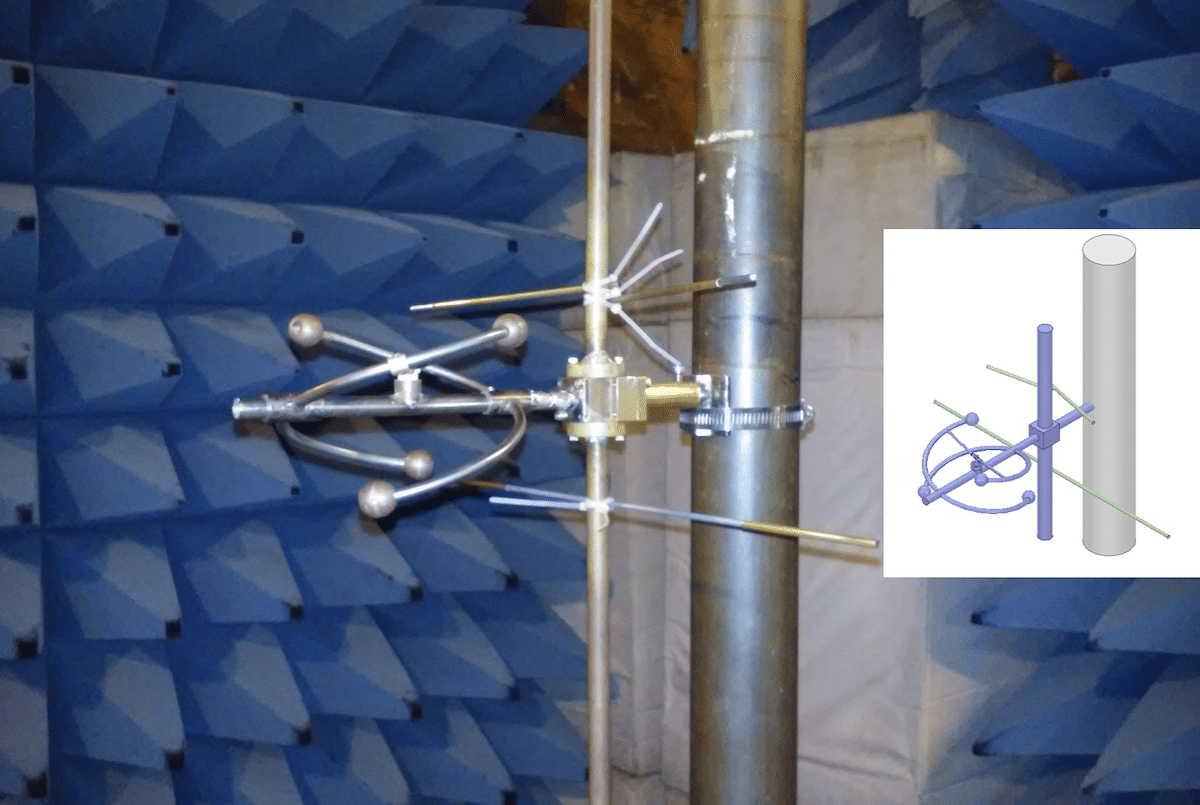

Dielectric’s idea is to provide FM broadcasters with a more efficient and economical antenna modeling process. FM broadcast antenna manufacturers today build physical models and collect measured data to verify antenna patterns – a time-consuming and burdensome process. Dielectric’s petition proposes that the FCC allow FM antenna manufacturers to transition to computer-based antenna modeling using computational methods – an approach widely used in other broadcast products. TV station antenna modeling has used this technique since 2017.

Long overdue

“This is simply long overdue,” said Dielectric’s Vice President of Engineering John Schadler. “FM is the only FCC service that still requires a physical range measurement, and anyone who has worked with range measurements knows that accurately measuring radiation patterns is extremely difficult. Simulated pattern verification is much more economical with less chance of error — it just makes sense.”

Schadler believes the clearance to leverage simulated antenna modeling will also result in better accuracy for broadcasters and yield results that are superior to traditional range measurement proofs. “Since simulations are done in a true free space environment, any issues with the range or anechoic chamber and with the surrounding environment are eliminated, resulting in more reliable azimuth patterns and H/V ratios.”

Dielectric claims the use of software also eliminates the lengthy set-up and take down time of models and the need for a technician to adjust the model and take data points by hand. This removes mechanical tolerances and human error affecting the data. Another advantage of designing in a virtual environment is that the geometry can be completely optimized and not compromised by time, materials and tolerances.